The Importance of AI for Manufacturing

Department of Energy data, predictive maintenance can provide savings of 8% to 12% over preventive care and reduce downtime by 35% to 45%. Extending the life of machinery and limiting unwanted shut-downs has a positive environmental–as well as financial–impact. AI refers to the algorithms computers use to carry out “intelligent” tasks with superhuman speed and accuracy–but without the need for human input.

The best kind of AI is the kind that can think and make decisions rationally and accurately. Let’s explore some of the important trends in artificial intelligence technologies in the manufacturing industry to get a clearer picture of what you can do to keep your business up to date. At the end of this blog, it is fair enough to say that Artificial intelligence is strongly paving its way in various industries, but manufacturing businesses are experiencing tremendous growth.

AI use cases in manufacturing

It is also essential for manufacturers to have a deep understanding of their business processes and how they can be optimized using AI solutions. Manufacturers need to adopt a holistic approach to drive growth and remain competitive in today’s market. Top management must take the initiative to embrace AI solutions and make informed decisions aligning with the business objectives.

The intersection of AI and industry brings forth complex challenges that demand careful consideration, transparency, and a commitment to fairness. To use an example, data can tell a manager that if their team nudges their equipment’s run rate up so as to boost production volumes, it could result in significant damage. The system may also find that graphic sleeves on a bottle of pop are being stretched, and that therefore production methods need to be changed so that the manufacturer remains within spec. How awesome would it be if you could detect a machine failure … before it happens?

Inventory management

Maintaining fully automated continuous flow, the company aims to optimize warehouse processes. It quickly checks if the labels are correct if they’re readable, and if they’re smudged or missing. If a label is wrong, a machine takes out the product from the assembly line.

- Costly machine maintenance, inefficiencies, and faulty products are some of the many issues plaguing the manufacturing industry.

- To locate and eliminate inefficiencies, manufacturers may use AI-powered process mining technologies.

- Implementing AI-based technologies has inevitably changed the way goods and services are planned and produced today.

- It helps you solve a particular problem by taking historic evidence in the data to tell you the probabilities between various choices and which choice clearly worked better in the past.

- This capability can make everyone in the organization smarter, not just the operations person.

Because of AI automation, employees can spend less time on mundane work and double down on the more creative elements of their job, increasing their job satisfaction and empowering them to achieve their potential. I am committed to resolving complicated business difficulties into simplified, user-friendly solutions, and I have extensive experience in Power Apps development. I thrive in integrating cutting-edge technology to optimise process efficiency, leveraging intermediate knowledge in Azure, Cognitive Services, and Power BI. My interest is developing dynamic apps within the Power Apps ecosystem to help organisations achieve operational excellence and data-driven insights. People often use the terms AI and machine learning interchangeably, but they’re two very different things. Machine learning puts data from different sources together and helps you understand how the data is acting, why, and which data correlates with other data.

Software Services

For instance, engineers can use ML technology to spot unknown anomalies and faulty components in production lines. Unlike some other industries, generative AI technologies like ChatGPT seem less likely to have an impact on manufacturing. AI-powered software can help organizations optimize processes to achieve sustainable production levels.

All this measuring, feeling, and seeing that my sensory helpers are doing really adds up. I’m supported in this by artificial intelligence, which knows all the standards for our production steps by heart and can immediately spot when deviations from them occur. AI-driven analytics can also be applied to customer and supplier interactions and buying habits. This helps manufacturers maintain high customer satisfaction with relatively little effort. As we come to the end of our deep dive into AI in Manufacturing, it’s essential to recognize that the potential of AI-driven manufacturing is boundless.

Defect detection, predictive maintenance, liquid level analysis, asset inspection are all being shaped by AI solutions based on computer vision and machine learning. Greater efficiencies, lower costs, improved quality and reduced downtime are just some of the potential benefits. High-value, cost-effective AI solutions are more accessible than many smaller manufacturers realize.

They can assemble complex products and predict/prevent equipment failures by analyzing sensor data, reducing downtime, repair costs, and improving worker safety. Boeing is leveraging AI in manufacturing to simplify complex tasks and optimize processes. It’s using machine learning algorithms and computer vision-based techniques to identify patterns in data and make recommendations for designs, supply chain efficiency, and inventory optimization.

Modernizing Demand Forecasting, Supply Chain, and Predictive Maintenance

It helps to improve the efficiency of the maintenance process and reduce overall maintenance costs and time. Using machine learning, manufacturers can predict future demand and adjust inventory levels accordingly. Overall, incorporating AI into logistics planning leads to greater supply chain visibility, shorter lead times, and less waste. One of the most popular applications of AI in manufacturing is predictive maintenance.

Think of AI algorithms scrutinizing mountains of data to help manufacturers prevent breakdowns before they occur. These AI applications could change the business case that determines whether a factory focuses on one captive process or takes on multiple products or projects. In the example of aerospace, an industry that’s experiencing a downturn, it may be that its manufacturing operations could adapt by making medical parts, as well. The feedback would help the manufacturer understand exactly what parameters were used to make those parts and then, from the sensor data, see where there are defects. In DRAMA, Autodesk plays a key role in design, simulation, and optimization, fully taking into account the downstream processes that occur in manufacturing.

Steel Manufacturer Reduces Scrap Rates – and Costs – with AI

Modern manufacturing generates an avalanche of data, from production metrics to supply chain dynamics. AI’s prowess lies in its ability to sift through this data and extract meaningful insights. Manufacturers can now make informed decisions, optimizing production schedules, anticipating demand fluctuations, and mitigating supply chain disruptions. With an AI-integrated supply chain, prepare for real-time inventory management, valuable vendor insights, and raw material price forecasting. We do need the process owner and the sponsorship of the management to know that this takes time. AI makes it possible for humans and robots to operate together in a factory in a safe and effective manner.

Machines imbued with AI can learn from real-time data, making decisions that optimize processes, reduce inefficiencies, and drive resource utilization to new heights. Predictive maintenance analyzes the historical performance data of machines to forecast when one is likely to fail; limit the time it is out of service; and identify the root cause of the problem. Indeed, computer vision is playing a key role in the overall quality assurance processes in the manufacturing sector. Industries that are benefiting from its role in production process automation include electronics, automotive, general-purpose manufacturing and many, many more. Recognizing the power of this technology, ERP vendors are introducing AI in their software to give manufacturers an all-in-one solution for managing enterprise data and processes. However, manufacturers are still unsure how to incorporate AI into their everyday practices.

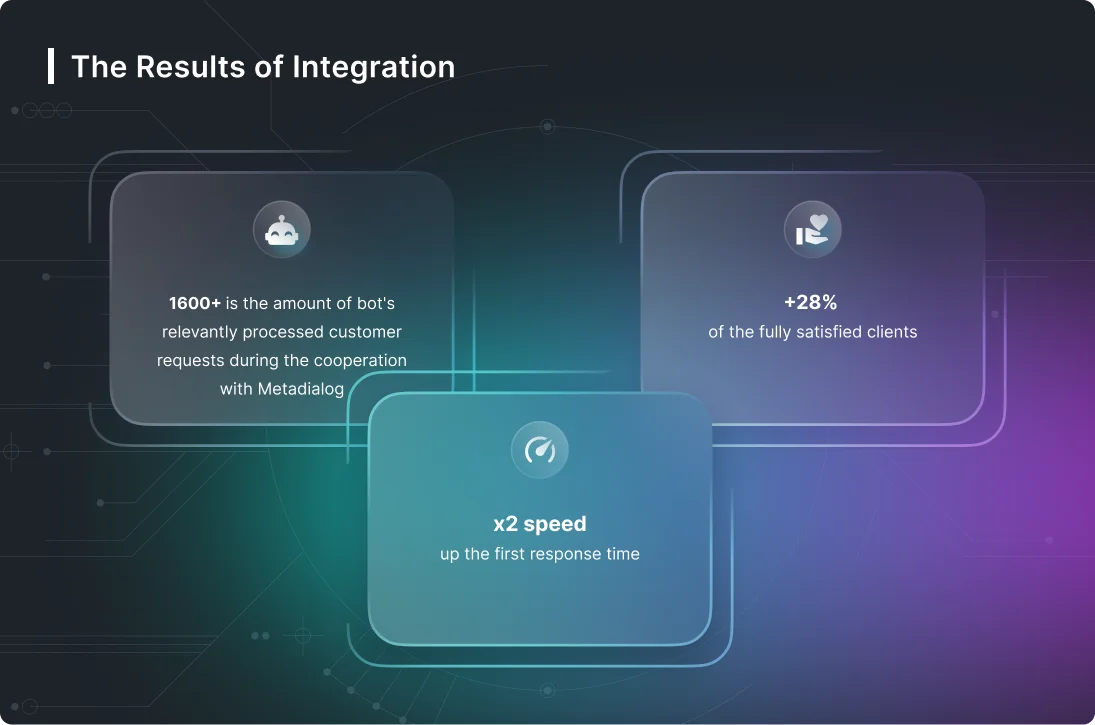

Read more about https://www.metadialog.com/ here.